Wafer Fabrication Process Flow - 18 images - semiconductor wafer fabrication process steps jefar net patent us6889178 integrated wafer fabrication production ppt ee580 solar cells todd j kaiser powerpoint presentation free. Probe Station and Microscope Etching.

What Is Silicon Wafer Sumco Corporation

Draw cross sections showing the metallization sequence of basic operations.

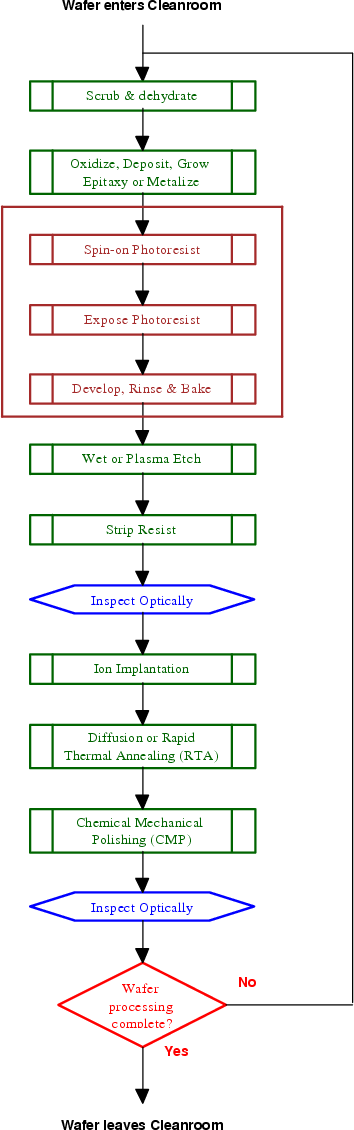

. Dicing of the Wafer Testing and Inspection of a Single ASIC. 401 Products built using this procedure must. The semiconductor manufacturing process flow when highly simplified can be divided into two primary cycles of transistor and interconnect fabrication.

Wafer Processing Oxidation Photography Etching Film Deposition Interconnection Test and Package. The silicon wafers so familiar to those of us in the semiconductor industry are actually thin slices of a large single crystal of silicon that was grown from melted electronic grade polycrystalline silicon. The manufacture of each semiconductor components products requires hundreds of processes.

Ad High Quality Roll Chip Bumping Services in North America. Draw cross sections showing the doping sequence of basic operations. Wafer fabrication process flow wafer fabrication process and measurement tools wafer fabrication process chemistry andphysics reliability physics and defect generation and control.

Use a large grit to coarsely grind the wafer and remove the bulk of the excess wafer thickness. 14 Wafer fabrication 141 Wafer separation and surface refinement At first the single crystal is turned to a desired diameter and then bedight with one or two flats. The second flat is used to detect the type of the wafer crystal orientation.

Explain the definition and use of a composite drawing and mask set. Process flow diagram for the production of semiconductor grade electronic grade silicon. Wafer thinning is implemented during different process steps as the wafer moves into the manufacturing process flow.

UBM 1 UBM 2. The process flow is shown in Figure 46. This preview shows page 610 - 612 out of 716 pages.

Bumped Diced and Tested Final Testing of the Tile Bonding at Low Temperatures Detector Conductor Passivation Si. The larger first flat allows an precise alignment of the wafer during manu-facturing. Back EndBE Process Wafer Back Grinding The typical wafer supplied from wafer fab is 600 to 750μm thick.

The overall process flow of wafer manufacturing The manufacturing process of the chip can be roughly divided into the wafer processing process Wafer Fabrication the wafer probe process Wafer. Gold Copper Nickel IndiumTinLead Lead-Free. The fabrication process is foundry CMOS compatible Zhao and Hua 2004.

After the ingot first gets sliced into the individual wafer the wafer will be planarized multiple times during the front-end of line FEOL manufacturing process. After sorting the entire manufacturing process is divided into eight steps. Ad Up To 150mm GaAs Wafers w3-Step Polishing For High Quality Products.

Single Crystal Silicon Wafer Fabrication. The transistor cycle is the basis of the most advanced chips see Figure 2. Ad Use Our Wafer Processing Devices For An Efficient Wafer Processing Solution.

Get A Free Quote Today. The mask layer can be photoresist polyimide or. It starts with a CMOS wafer.

Identify the parts of a wafer. Identify and explain the four basic wafer operations. The first step is to define the MEMS structure and protect on-chip CMOS circuits.

Enjoy Reliable Support From Our World Class Team Of Experts. However the main wafer thinning happens during the back-end of. 3 Process Flow Chart Bonding ASIC.

1st step. Characterization of defects and screening effectiveness. Draw a flow diagram of the circuit-design process.

Wafer thinned down to the required thickness 50um to 75um by abrasive grinding wheel. With a wafer as the starting point it involves epitaxial silicon Epi dielectric deposition photolithography.

Improving The Sic Wafer Process Power Electronics News

![]()

Basic Semiconductor Manufacturing Process

![]()

The Process Of Fabrication 1 Silicon Wafer Pretreatment To Maintain Download Scientific Diagram

0 Comments